Part of Marrill Group Limited’s added value is our ability to engineer a product at the design stage to ensure that it is as efficient, robust, functional, and cost-effective as possible.

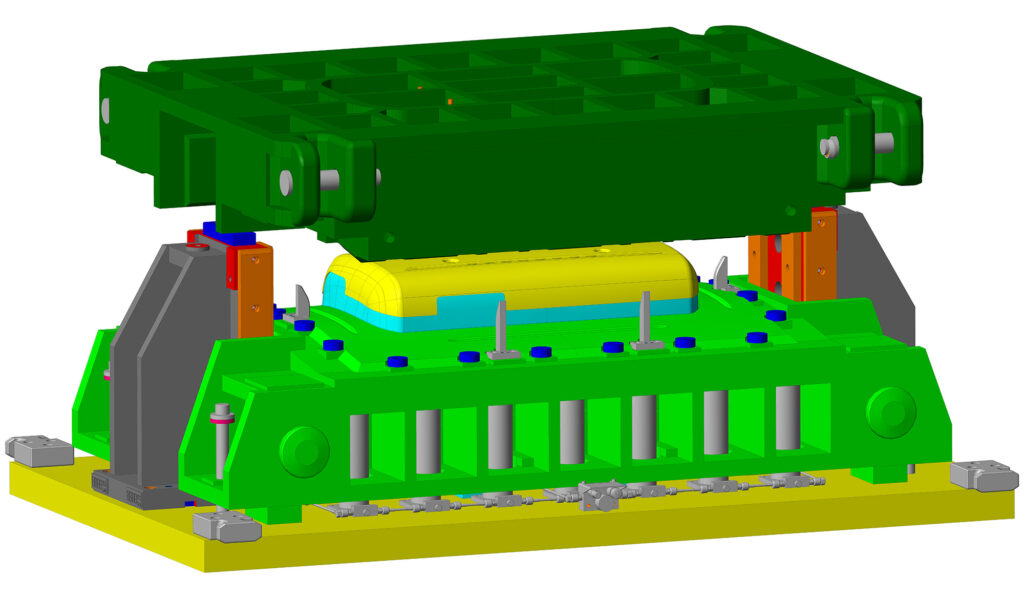

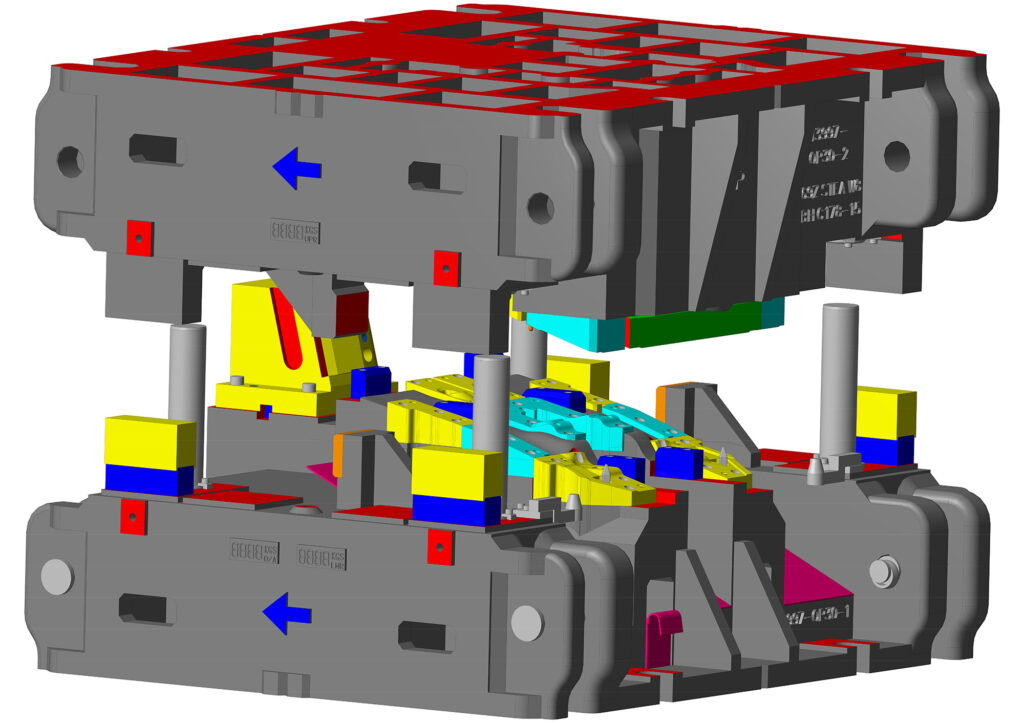

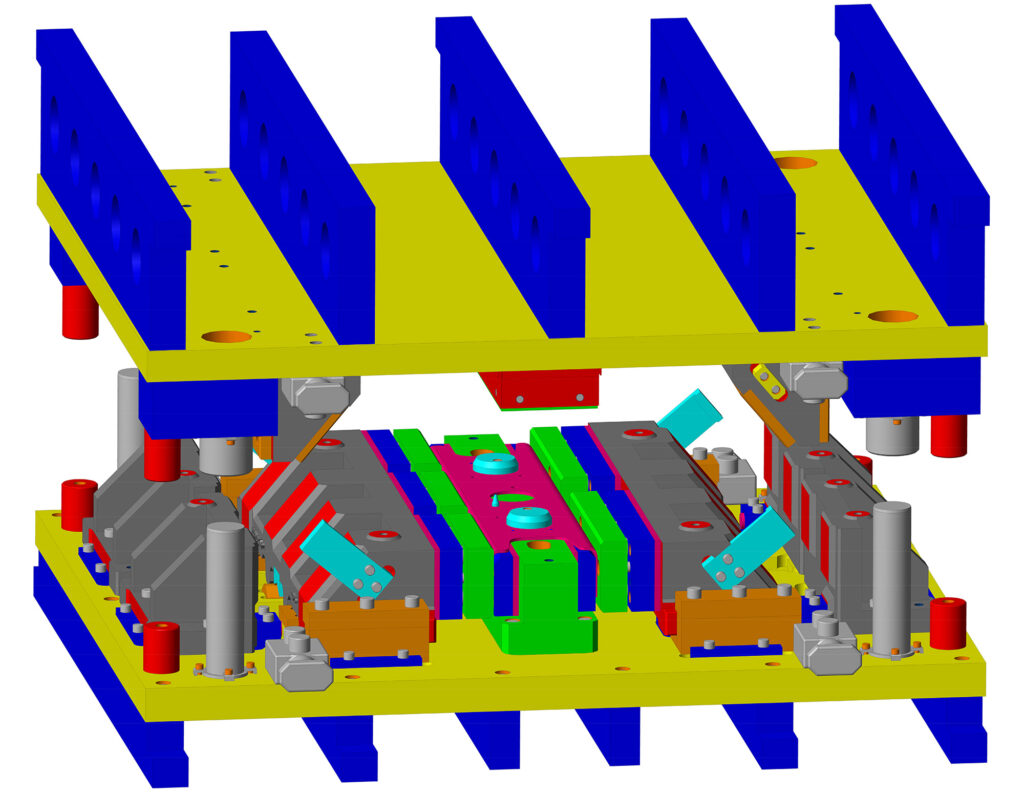

Using the latest CAD technology and our cutting-edge inspection facilities, we digitally design, re-design and refine the product, conducting feasibility studies – and addressing and eliminating any concerns before production.

This process helps us to achieve the perfect end result – and at this stage, we can also accurately calculate the most efficient use of materials ahead of high-volume production.

Features

- Full 2D and 3D Modelling

- Component design modelling

- 3 and 5 axis CAM programming

- 2 and 5 axis laser component programming

- Full Analysis, Progress and Blank Design

- Full 2D and 3D Machining

Simulation – Using our experience to add value

We take what we learn at the design and simulation stage and use it during manufacturing, tooling and production. This helps us to better understand and improve product performance.

Alternatively, we can pass the finished design, castings and prototype back to the customer for production within their own manufacturing facility.

Features

- Blank Size Engineering (BSE)

- Die Evaluation

- Formability Simulation

- Exporting Simulation as .avi format